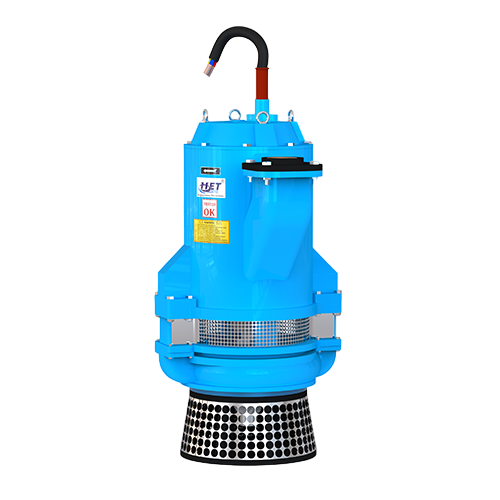

For difficult slurry applications, the “HET” “SSEW” Series is an excellent Non-Clog Submersible Slurry Pump option. Its distinct design distinguishes it with a Twin Volute and a Non-Pressurized single/dual mechanical seal. Slurry with a specific gravity of up to 2.8 and solid concentrations of up to 65% can be easily handled by this pump. Seal and motor integrity are maintained by the non-pressurized mechanical seal assembly, which protects revolving parts from hydraulic pressure. Furthermore, the pump casing performs better than conventional single-volute designs at distributing shaft stresses when handling variable-density slurry.

The “HET” “SSEW” Series is well-suited for intricate slurry applications, such as the removal of industrial waste, because it has an oil-cooled motor, inducer, and temperature sensors. It is also highly corrosive and suitable for heavy sludge and slurry operations in various industries. Select this series for unparalleled functionality, cutting-edge design, and unwavering dependability in demanding industrial settings.

Performance Technical Data :

| Head | – | Up to 130 mtr. |

| Discharge | – | Up to 1000 m3/hr. |

| Soild Size | – | max. Up to 40 mm |

| SPEED | – | 1450 / 960 rpm |

| Delivery Size | – | 100 MM / 150 MM / 200 MM |

| Delivery Type | – | Flange type |

| Motor Rating | – | 12.5 to 150 HP |

| Supply | – | 3Ø, 50Hz/60hz, A.C. |

Special feature /Advantage :

- “HET” Motor enclosure prevent electrical motor heating burnout.

- “HET” Motor with reserve power for direct online starting when its settled sump solids.

- “HET” Pump equipped with non-pressurise mechanical seal due to that no effected pump media pressure .

- “HET” Pump equipped with Armoured / Unarmoured Cable as per customer requirement.

- “HET” Pump equipped with agitator / Inducer to break-down and re-suspend settle solids at suction area.

- “HET” Pump equipped with motor cooling jacket & “H” Class winding & Copper rotor due to that more efficient and perform batter in heavy slurry application.

- “HET” Pump casing is twin volute design due to that pump pefrom well and due to that avoid vibration effect and run smoothly in heavy slurry application.

- “HET” Pump provided additional feature on request like Thermistor Sensor for against heat protection of motor in dry run condition ,Moisture Protection for water ingress in motor .

- “HET” Pump equipped with non-drive end double ball bearing and drive end also double ball bearing or angular contact bearing oversize for extend the motor life in slurry application.

- “HET” Pump wetted part are offer with Ni-Hard material of casing or Tungsten /Ceramic coating ( as per application) with Semi open Impeller material with Ni-hard or Hi-Chrome for better performance and better Pump life in Slurry application.

Material Specifications :

| Motor Part | – | Cast Iron / SG Iron |

| Impeller | – | Stainless Steel / Ni-hard |

| Agitator / Inducer | – | Stainless Steel |

| Casing | – | Cast Iron |

| Mech. Seal | – | Non Pressurize Tc /Tc |

| Rubber Part | – | nitrile / viton rubber |

| Fastner | – | Stainless Steel |

| Cable | – | Unarmoured/ Armoured type |

| – | PvcDouble sheathed with 10 mtr. Length | |

| Motor Winding | – | H Class Copper Wound |

NOTE: **Also, these pumps can be ordered in any quantity the customer requests, using construction materials like as S.S. 304, S.S. 316, NI HARD, HI CHROME, or any other material. We can also provide any special construction materials needed for a particular part based on the application.**

Application Area :

- Industrial Waste Slurry

- River Bed Slurry

- Sea Water Slurry

- Slit Removal

- Sludge Removal

- Ash Handling

- Blast furnance Slurry waste

- Coal handling

- Contaminated effluents

- Slurry & Sludge Pits

- Iron ore Slurry

- Oil Slurry

- Salting Plant

- Industrial & Municipal slurry waste

Industries :

- Mill scale , Iron Ore & Pallet Industries

- Steel Plant / Power Plant / Refineries

- Steel Plant / Power Plant / Refineries

- Textiles / Chemical / Various Industries / Jetty Site

- Mineral Ore processing units

- Water Treatment Plants /CEPT / ETP / STP

- Removal of sand from Dam, River & Sea Water Galleries & penstock