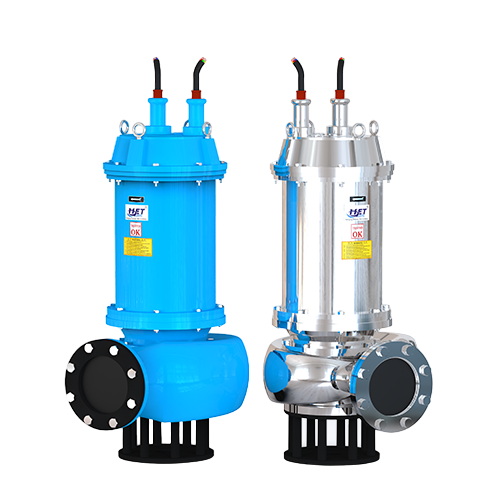

The pumps in the “HET” brand’s “HDSEW” series are single shaft, single stage, non-clog type, submersible, equipped with temperature and moisture sensors, dual mechanical seals, open/semi-open/close, vortex, single vane, two vane, and multi-vane impellers. “F” class A.C. squirrel cage induction motor. These pumps have a robust design and excellent performance capacity.

High discharge submersible pumps are made by “HET” and are part of the “HDSEW” series. These pumps have an enormous capacity to release water, especially in situations involving the management of sewage and sludge. They have an output of more than 8 inches, which allows them to discharge more water than other pumps with a lower motor rating. Usually, primary and secondary treated sewage is used with this configuration. Because of their carefully designed impellers, these pumps offer excellent dependability against clogging and the capacity to readily clear things that have become lodged inside the pump. The pumps are capable of managing liquids and solids beginning with 20–125 mm in diameter. The most popular uses are dewatering applications in water treatment, wastewater treatment, and industrial effluents; they include multiple and nagarpalika MLD Projects, Dame Site, return activated sludge (RAS), surplus activated sludge (SAS), and waste activated sludge (WAS) in sewage treatment. The pumps provide the maximum flexibility and dependability thanks to their highly efficient submersible motors, full feature pump monitoring systems, and VFD operation options.

Performance Technical Data :

| Head | – | Up to 75 mtr. |

| Discharge | – | Up to 2500 m3/hr. |

| Soild Size | – | max. Up to 150 mm |

| SPEED | – | 1450 / 960 / 750 rpm |

| Delivery Size | – | 250 mm/ 300 mm/ 350 mm / 400 mm |

| Delivery Type | – | Flange type |

| Motor Rating | – | 30 to 250 HP |

| Supply | – | 3Ø, 50Hz/60hz, A.C. |

Special feature /Advantage :

- Impellers are available with Single Vane or two or multiple vanes in semi-open and enclosed type to be able to cater to a wide range of application areas

- Pump Equipped with Thermal Sensor & Moisture Sensor

- Double mechanical seal with back to back arrangement to ensure there is no ingress of pumping liquid in the motor

- Available design with cooling Jacket & Agitator

Material Specifications :

| Motor Body | – | Cast Iron |

| Other Part | – | Cast Iron |

| Impeller | – | Stainless Steel |

| Casing | – | Cast Iron |

| Cable | – | PVC Double sheathed with 10 mtr. Length |

| Mech. Seal | – | Sic / Sic & Tc /Tc |

| Hardware | – | Stainless Steel |

| Rubber Part | – | Nitrile Rubber |

NOTE: **These pumps can also be ordered in any quantity the customer requests, using construction materials like as S.S. 304, S.S. 316, NI HARD, HI CHROME, or any other material. We can also provide bespoke construction materials for any portion that is needed, depending on the application.**

Application Area :

- Trench and tunnel

- Construction site

- Drain water

- Drainage water

- Saline water

- Storm water

- Biogas Plant waste water

- Etp plant

- Contaminated effluents

- Manhole

- Pond , Pits, Mine

- Hospital waste water

- Washroom waste water

- Industrial & Municipal waste water

Industries :

- Municipal Corporations

- Steel Plant / Power Plant / Refineries

- Manhole / Septic Tank

- Textiles / Chemical / Various Industries / Jetty Site

- Municiple & Nagarpalika waste water

- Industries / Water Treatment Plants /CEPT / ETP / STP

- Domestic Sludge Handlingl/Slurry Handling / Stone